From Mic-Mac to mishmash — that’s essentially the evolutionary arc of hockey stick construction.

The most popular sticks these days are custom; one-piece composites — typically of graphite, though exotics such as Kevlar and titanium are also used, and occasionally coatings such as nickel cobalt are applied for added strength.

In laminate-style two-piece sticks, layers of glue and wood, fiberglass or graphite — or some combination of wood, fiberglass and graphite — are used for the shafts. That’s a long way from the one-piece, hand-carved hunks of hornbeam formed by indigenous Canadian Mi’kmaqs into the first commercially produced sticks, in the late 1800s.

From Tradition to Technology

When players today ask, “what are hockey sticks made of?”, the answer reflects over a century of innovation in hockey stick materials. From solid wood origins to today’s composite marvels, the evolution of materials has shaped how players shoot, pass, and handle the puck.

Early designs emphasized strength and durability, while modern manufacturing focuses on precision, flexibility, and lightweight control. Innovations in carbon fiber sticks, fiberglass, and Kevlar have made today’s sticks more efficient and customizable than ever — allowing athletes to tailor every element, from flex to curve and grip options, to their style of play.

As modern hockey stick technology continues to evolve, new eco-friendly materials are emerging, paving the way for a future where performance, sustainability, and reduced hockey stick weight go hand in hand.

Wooden Hockey Sticks: The Original Material

Hornbeam trees, native to Nova Scotia, are also referred to as “ironwood” for the material’s durability and “stinkwood” because of its strong aroma when cut. As the popularity of the game and of Mic-Mac sticks grew, hornbeam supplies grew scarce, and yellow birch became the wood of choice.

Those sticks were carved into one piece. By the 1920s, patented designs emerged for two-piece wood sticks, in which the blade is inserted and glued into a joint in the shaft. Wooden shafts were typically laminated birch, maple, aspen, Ramin and/or ash, while the blades were usually the same wood as the shaft. Beginning in the 1950s, blades were wrapped in woven fiberglass material.

Wood hockey sticks typically are heavier than their composite counterparts, a useful trait when trying to dig a puck out of a battle in the corner. They’re cheaper and more durable. However, lighter sticks are widely considered to produce harder, quicker shots — which is why they’ve become far and away the more popular option among serious players.

Pros of Wooden Hockey Sticks:

- Durable and cost-effective for beginners and recreational play

- Provides traditional “feel” for puck handling

- Easier to repair or replace

Cons of Wooden Hockey Sticks:

- Heavier than composite sticks, reducing shot speed

- Less consistency in flex and responsiveness over time

- More prone to absorbing moisture and warping

Learn more about how stick materials have evolved in our guide on the evolution of hockey sticks.

Aluminum Hockey Sticks: A Short-Lived Trend

Briefly, fueled by a 1990s Wayne Gretzky endorsement deal, aluminum-shafted sticks blossomed in popularity. But, by the end of the century, aluminum sticks — usually aluminum shafts with a wooden blade — were supplanted on the pro level by custom, one-piece composite sticks.

Why aluminum didn’t last:

- Heavier than composites and less natural in feel

- Transferred vibrations sharply to the player’s hands

- Limited flexibility and customization

Although aluminum offered an innovative step between wood and composite, it ultimately couldn’t compare to the power, precision, and customization that modern materials provide.

Composite Hockey Sticks: The Modern Standard

A composite shaft more closely approximates the feel and flexibility of wood while retaining the relative light weight of aluminum. A one-piece composite stick can be customized to a dizzying degree, tapering the shaft to lower the kick point (the point at which the shaft flexes), shaft shape (rounded or square), lie, vertical angle and curve of the blade, etc.

Modern composite sticks use a blend of carbon fiber, fiberglass, resin, and sometimes Kevlar for added strength and vibration dampening. These materials allow for precise control over flex, balance, and durability, creating a stick that feels responsive and powerful in every play.

Performance benefits of composite hockey sticks:

- Lightweight design enhances shooting speed and puck control

- Consistent flex and energy transfer for improved shot accuracy

- Customizable features — curve, lie, grip options, and kick point — to fit any playing style

- Superior durability compared to wooden alternatives

Want to know more about how flex affects your shot? Check out our guide to hockey stick flex.

How Composite Hockey Sticks Are Made

Clearly, these are not being carved from a tree. How are they made? Composite stick construction combines advanced materials with precision molding to ensure consistent performance across all types of hockey sticks.

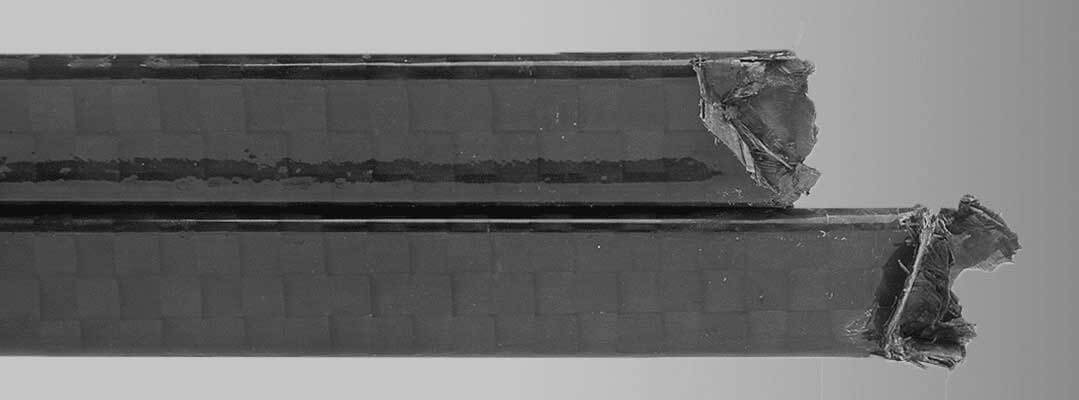

Shaft Construction:

- Carbon fiber threads woven together and coated with plastic resin

- As many as 15 sheets of carbon fiber fabric are fused together, layered in opposite directions for strength, to form the hollow shaft

Blade Construction:

- Blades begin with a hard foam plastic core wrapped in graphite

- Blades are glued to the shafts

- A graphite sock is applied to the still-straight blade

- Several subsequent layers of graphite are glued to the blade

Finishing & Customization:

- A mold — whether custom for professional players or a mass production shape — puts the specified curve and vertical angle on the blade, and bonds the blade to the shaft

- Excess graphite is removed, and the blades are sanded, buffed, painted and dipped in urethane

- The graphics are added using decals or silk screens, often applied over a base paint layer for extra visual appeal

For players looking to personalize their setup, Pro Stock Hockey offers hockey stick customization.

Comparing Stick Materials: Wood vs. Aluminum vs. Composite

When comparing hockey stick materials, it’s clear that every option plays differently — from the solid feel of wood to the light, responsive power of today’s advanced composites.

- Weight: Composite sticks are the lightest, followed by aluminum, with wood being heaviest.

- Durability: Composites resist cracking and moisture damage better than wood; aluminum is durable but less flexible.

- Cost: Wooden sticks are most affordable, while top-tier composite models come at a premium.

- Performance: Composite sticks dominate in speed, accuracy, and customization — suitable for serious players at all levels.

If you’re new to the game, explore our comparison of youth vs. junior hockey sticks to find your best fit.

The Future of Hockey Stick Technology

Tomorrow’s hockey sticks will blend sustainability, smart design, and enhanced materials. Manufacturers are exploring bio-based resins, recycled carbon fibers, and embedded sensors that track flex and shot velocity. Continued innovations promise not only better gameplay but also a smaller environmental footprint for players and brands committed to eco-conscious performance.

Find Your Perfect Hockey Stick Today

From classic wooden models to state-of-the-art carbon fiber sticks, the material you choose directly affects your feel, power, and control on the ice. At Pro Stock Hockey, we offer a wide selection of NHL player hockey sticks and goalie sticks to match every level and playing style.

Shop All Hockey Sticks to find your ideal fit today!